COOPERAGE AUTOMATION SOLUTIONS Preserve Tradition, Enhance Production

Alliance Automation delivers advanced automated solutions for the cooperage industry, combining robotics, precision machining, and material handling to streamline barrel production. Our systems support key processes such as stave preparation, assembly, and finishing to ensure consistent quality, efficiency, and repeatability. By reducing labor demands, improving workplace safety, and leveraging technology, we help cooperages scale their operations, lower costs, and preserve the craftsmanship and tradition that define the industry.

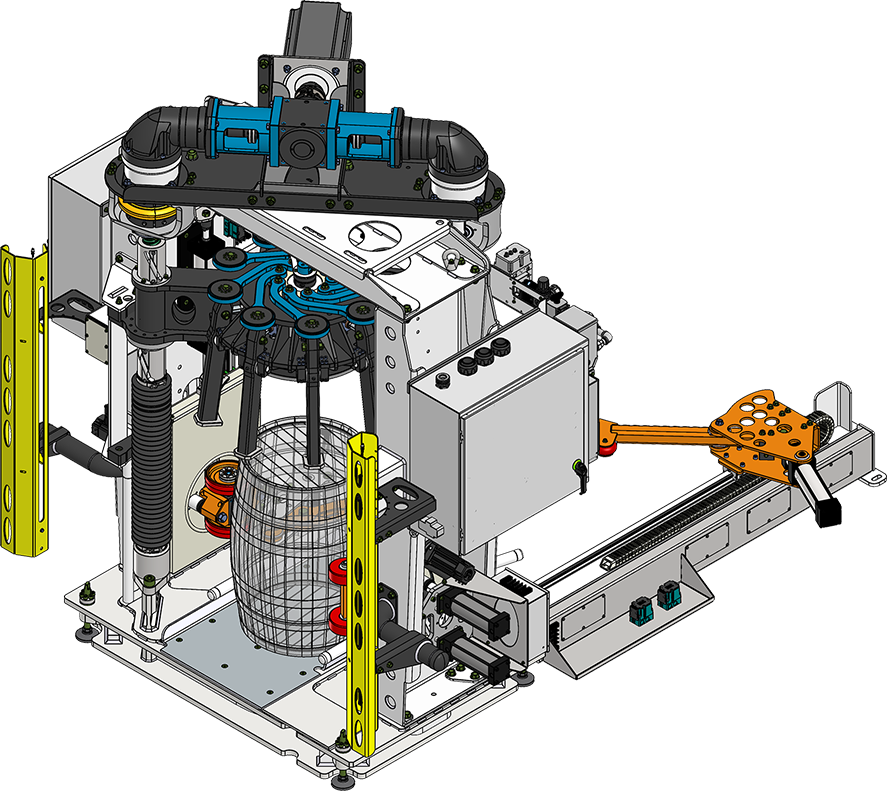

Head Up

Fastest Cycle Time on the Market

✓ Peak rate of 50 barrels per hour

Robust Machine

✓ Full H-Frame rigid construction

✓ Safety PLC controlled and light curtains increase safe operation

Barrel Inverter

✓ Reduces operator manual labor

✓ Flips the barrel for faster hoop placement

Automatic Load & Unload

✓ Automatically load a barrel into position from manufacturing line

✓ Kicks barrel out of machine for easy removal

Operator Control Panel

✓ Intuitive operation

✓ Simple push-button operation

No hydraulics = No mess or rejected product

Force & distance feedback monitoring to ensure proper hoop placement

Synchronized ball screws to ensure uniform pressing of the hoops

Less Maintenance than Hydraulic

Efficient Barrel Head Installation

The automated head up system brings speed and consistency to barrel assembly by precisely aligning and installing barrel heads. This solution reduces the need for heavy manual labor, improves worker safety, and ensures a tighter, more reliable fit every time. By streamlining one of the most critical steps in cooperage, it boosts production capacity while maintaining the high-quality standards expected in handcrafted barrels.

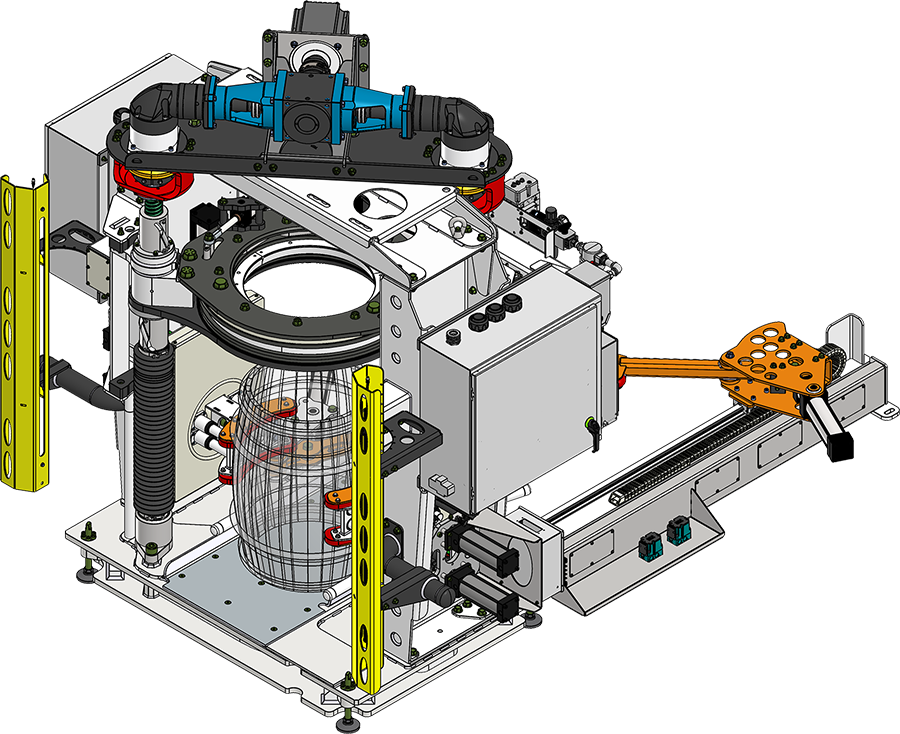

Hoop Driver

Fastest Cycle Time on the Market

✓ Peak rate of 50 barrels per hour

Robust Machine

✓ Full H-Frame rigid construction

✓ Safety PLC controlled and light curtains increase safe operation

Barrel Inverter

✓ Reduces operator manual labor

✓ Flips the barrel for faster hoop placement

✓ Automatically spins the barrel 180° to allow for easy hoop alignment

State-of-the-Art Maxon Gas Train & Burner Controls

✓ Provides almost instantaneous barrel combustion

✓ Allows for four very distinct char levels and characteristics

Automatic Load & Unload

✓ Automatically load a barrel into position from manufacturing line

✓ Kicks barrel out of machine for easy removal

Operator Control Panel

✓ Intuitive operation

✓ Simple push-button operation

No hydraulics = No mess or rejected product

Force & distance feedback monitoring to ensure proper hoop placement

Synchronized ball screws to ensure uniform pressing of the hoops

Less Maintenance than Hydraulic

Precision and Efficiency in Hoop Driving

The automated hoop driver streamlines barrel production in the cooperage industry by precisely and efficiently securing hoops onto barrels. Designed for consistency and safety, it eliminates the strenuous manual process, reduces labor demands, and ensures each hoop is driven with uniform force. This automation not only increases throughput but also enhances product quality, helping cooperages meet growing demand while maintaining traditional craftsmanship standards.

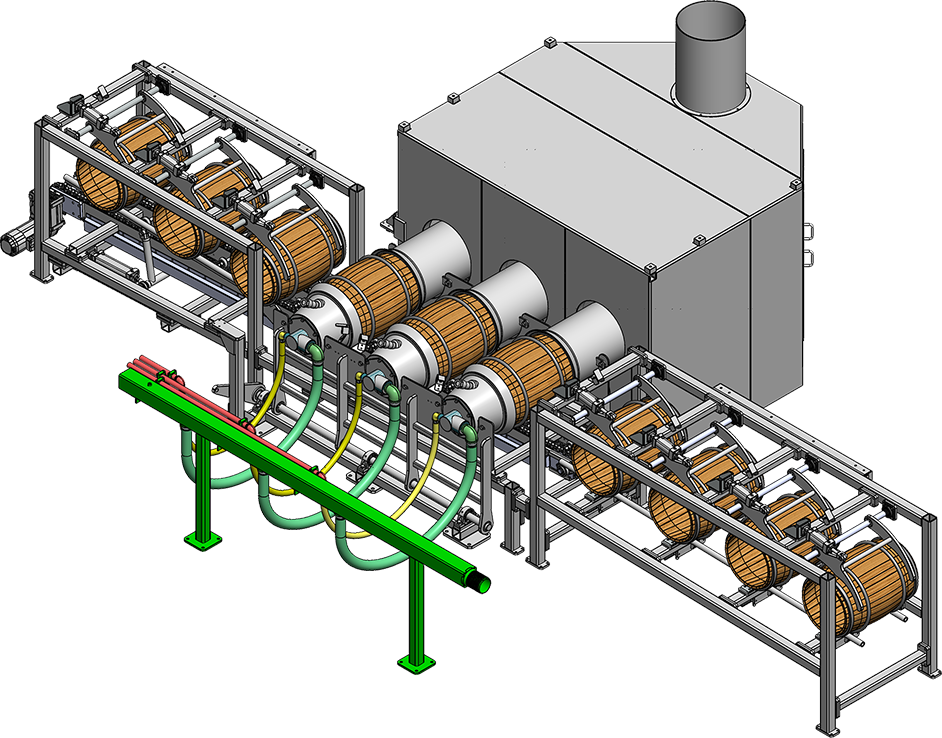

Horizontal Char

Eliminates Top Char Bias Found In Current Vertical Methods

Three Barrels Charred Simultaneously

✓ Peak rate of 100 barrels per hour

Spiral Flow Quench

✓ Extinguish char flame in its entirety

✓ Consistent barrel preparation for the crozer operation

State-of-the-Art Maxon Gas Train & Burner Controls

✓ Provides almost instantaneous barrel combustion

✓ Allows for four very distinct char levels and characteristics

Benefits of Cooperage Automation

Consistency Every barrel meets strict quality standards

Efficiency Faster production without sacrificing accuracy

Safety Automation reduces heavy lifting and repetitive tasks

Scalability Solutions grow with your business, from small shops to high-volume producers

Cooperage Processes We Support:

- Stave handling and sorting

- Precision machining and cutting

- Barrel raising, hooping, and pressing

- Finishing, sanding, and charring

- Automated inspection and quality control

Why you should Join the Alliance

When you partner with Alliance Automation you're getting more than just a robotic solution.

Alliance Automation is here to design, build and install a custom solution to fit your exact needs. Our products will solve your business challenges. How? We follow the Alliance Proven Process. Alliance Automation doesn’t just sell you a product; we get to know your business and find solutions to help you reach your goals.

What we offer:

- Project Review

- Risk Analysis and Risk Assessments

- Budgetary and complete project proposals

- CAD Designers

- Fabrication

- Toolmakers

- Machinists

- Mechanical Engineers

- Electrical Engineers

- Controls Engineers

- Project Managers

- Full Implementation teams

Experience the future of industrial automation today.

Design, automate, order and deploy your equipment with us today.