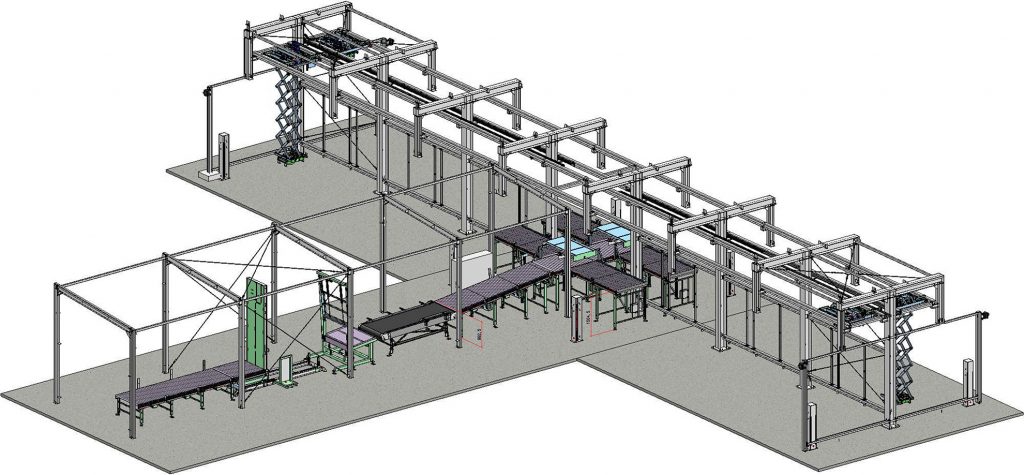

Multi Pallet Sorting Line (MPSL)

-

COMPONENTS

-

1. 2 Gantry Style Pick & Place EOAT

-

2. Stack Tippers

-

3. Inspection/Vision

-

4. Sorting Platforms (light blue)

-

5. Conveyors

-

6. Stackers (4pcs)

-

7. Stacking Places (up to 4x8=32places)

Customization based on your needs.

Combine with The Urban Sawmill

Increase the feed speed withThe Robotic Pallet Dismantler

Multi Pallet Sort Line

Do you sort many different pallets within your company?

That quickly becomes time-consuming and unprofitable.

Alliance Automation recognized this problem and has worked with an industry leading partner to provide our customers with the Multi Pallet Sorting Line (MPSL). This is the only flexible sorting line that stacks and registers all types and sizes of pallets for you. All pallets are automatically stacked, up to thirty types! This saves a lot of walking back and forth with pallets weighing 22 to 66lbs. This prevents unnecessary forklift traffic. You can repair any broken

pallets immediately.

Curious about how it works? Check out the videos below:

VIDEO LIBRARY

Multi Pallet Sorting Line

MULTI PALLET SORT LINE BROCHURE

Take a closer look at the Multi Pallet Sort Line brochure and discover how your company can benefit. Follow the link to download the brochure.

Sort and Repair Systems FAQ

- An average would be 2-6 stack positions.

- Some customers load one stack at a time, while others load double stacks.

- It is based on the number of sortation categories required for your daily production.

- You will want to know what grades you would like to sort too, and then we can size the line based on your needs.

- We have standard 48 x 40 Stackers, Adjustable Stackers (36″ -50″ sizes), and a Robotic Stacker that can be used for larger pallets and more flexibility.

- An average number would be 4-6 stackers after the repair line, and some companies put stackers up front on their sort systems so that ready-to-go pallets can be moved off the line right away.

- It is a preference. The swoop works fine but requires more interaction with the pallet and the operator.

- The Armadillo (chain) conveyor peels the pallets apart and singulate them better.

- It all comes down to budget. If you can make it work, the Armadillo style is better for the operator.

- We sell over-the-line stackers, and they are just not as popular. With over-the-line stackers, the entire main line is on hold while the pallet stops and the stacking process runs.

- When transferring a pallet down the line to a stacker, an off-the-line stacker allows the pallet to be swept off the main line, so the stacking takes place offline.

- You can get faster production with off-the-line stackers vs. over the line

- Sometimes, a sort line will have a stacker for pallets needing repair.

- Not recommended.

- Missing stringers – they can be broken but not missing entirely.

- Less than 2 bottom boards (will not transfer down the conveyor or into the stackers well).

- If you are talking about pallets that were repaired and not fixed correctly or graded wrong at sort, then:

- There is a full-length shelf on both sides of the stacker that lift and stack. If the repair operator did not put the bottom boards or a stringer on it could cause the pallet to be tilted, which would cause the stack to tip.

- If the operator missed those boards, it could also cause an issue with the stop finger on the entrance.

- Yes, adjustable stackers (36″ -50″ sizes) and a Robotic Stacker can be used for larger pallets and more flexibility.

- There is a changeover time to go from one size to another.

- Also, once you set the stackers up, we like to keep the adjustment range of that stacker within 6″ so we can put controlled funneling in place.

- 10-15 minutes

- This can vary depending on space and the needs of the customer.

- Yes, as long as you only need between 2-4 positions. If more positions are required, we must ensure we have room for the proper decline to allow gravity to work.

- Sometimes we add CDLR after the stacker if they require a longer outfeed.

- Yes, it would require some shared conveyors and transfers.

- It might also be a good application for a robotic stacker.

- We would need to play with the layout to address this one in more detail.

- Lead times vary on the complexity of the line.

- If you were looking for a line with Sort-Repair-Robotic Dismantling-Urban Sawmill all integrated, it would be roughly 20-24 weeks.

- It depends on the backlog at the time of order and how large or small the line is.

- 20-25 years

- Wood jambs, loose lumber, or non-repaired pallets with nails and “stuff” that get caught.

- There are so many variables and options that it is impossible to give a number.

- These are like legos, and some pieces and parts can be added to shapeshift and fit the lines to meet your production needs.

BENEFITS

- All types and sizes of pallets can be stacked automatically.

- Flexible design solutions for facilities with limited space.

- Registration of all sorted and repaired pallets.

- Reduce fork truck traffic in your facility.

- Able to process 250 – 500 pallets per hour.

- Inspection and selection of pallet types in seconds.

- Fewer people with easier workload.

You Can't Afford Not to Adopt Automation

Think automation is too expensive for your business? Think again.

Contact us today to learn how our solutions can save you money, improve your processes and solve your labor challenges.