-

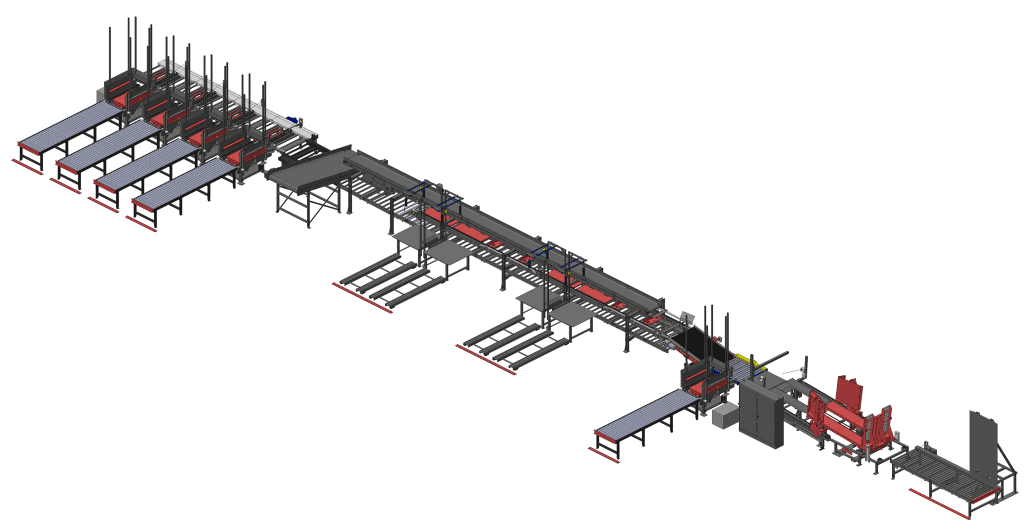

COMPONENTS

-

1. Stack Tippers

-

2. Inspection/Vision

-

3. Conveyors

-

4. 1, 2 or 3 Tier Lines

-

5. Repair Tables

-

6. Stackers

-

7. Material Handling Equipment

-

Robotic Dismantlers

-

The Urban Sawmill

-

Robotic Stackers

Customization based on your needs.

Combine with The Urban Sawmill

Increase the feed speed withThe Robotic Pallet Dismantler

Sort & Repair Systems

Fastest Sort & Repair Systems in the Industry

Sort & Repair Systems are not one size fits all. You need equipment that’s built like a tank, from a partner the industry relies on. Alliance Automation works with you to understand your business’s unique needs and challenges to provide the right amount of automation to fit your business. Customers report a decrease in sorting costs of 30% and an increase in sorting speed of 37% when they implement our lines. Mix-n-match the equipment to remove the heavy work out of your sortation and repair.

SORT & REPAIR SYSTEMS PRODUCT BROCHURE

Take a closer look at our Sort & Repair Systems and discover how your company can benefit. Follow the link to download the brochure.

SORT & REPAIR SYSTEM COMPONENTS

We also provide individual components for our Sort & Repair Systems. Download this brochure to learn more.

Sort and Repair Systems FAQ

- An average would be 2-6 stack positions.

- Some customers load one stack at a time, while others load double stacks.

- It is based on the number of sortation categories required for your daily production.

- You will want to know what grades you would like to sort too, and then we can size the line based on your needs.

- We have standard 48 x 40 Stackers, Adjustable Stackers (36″ -50″ sizes), and a Robotic Stacker that can be used for larger pallets and more flexibility.

- An average number would be 4-6 stackers after the repair line, and some companies put stackers up front on their sort systems so that ready-to-go pallets can be moved off the line right away.

- It is a preference. The swoop works fine but requires more interaction with the pallet and the operator.

- The Armadillo (chain) conveyor peels the pallets apart and singulate them better.

- It all comes down to budget. If you can make it work, the Armadillo style is better for the operator.

- We sell over-the-line stackers, and they are just not as popular. With over-the-line stackers, the entire main line is on hold while the pallet stops and the stacking process runs.

- When transferring a pallet down the line to a stacker, an off-the-line stacker allows the pallet to be swept off the main line, so the stacking takes place offline.

- You can get faster production with off-the-line stackers vs. over the line

- Sometimes, a sort line will have a stacker for pallets needing repair.

- Not recommended.

- Missing stringers – they can be broken but not missing entirely.

- Less than 2 bottom boards (will not transfer down the conveyor or into the stackers well).

- If you are talking about pallets that were repaired and not fixed correctly or graded wrong at sort, then:

- There is a full-length shelf on both sides of the stacker that lift and stack. If the repair operator did not put the bottom boards or a stringer on it could cause the pallet to be tilted, which would cause the stack to tip.

- If the operator missed those boards, it could also cause an issue with the stop finger on the entrance.

- Yes, adjustable stackers (36″ -50″ sizes) and a Robotic Stacker can be used for larger pallets and more flexibility.

- There is a changeover time to go from one size to another.

- Also, once you set the stackers up, we like to keep the adjustment range of that stacker within 6″ so we can put controlled funneling in place.

- 10-15 minutes

- This can vary depending on space and the needs of the customer.

- Yes, as long as you only need between 2-4 positions. If more positions are required, we must ensure we have room for the proper decline to allow gravity to work.

- Sometimes we add CDLR after the stacker if they require a longer outfeed.

- Yes, it would require some shared conveyors and transfers.

- It might also be a good application for a robotic stacker.

- We would need to play with the layout to address this one in more detail.

- Lead times vary on the complexity of the line.

- If you were looking for a line with Sort-Repair-Robotic Dismantling-Urban Sawmill all integrated, it would be roughly 20-24 weeks.

- It depends on the backlog at the time of order and how large or small the line is.

- 20-25 years

- Wood jambs, loose lumber, or non-repaired pallets with nails and “stuff” that get caught.

- There are so many variables and options that it is impossible to give a number.

- These are like legos, and some pieces and parts can be added to shapeshift and fit the lines to meet your production needs.

BENEFITS

- Easy maintenance and upkeep

- Low out of pocket expenses

- Reduce injury probability, fatigue, and workplace accidents

- Increase worker longevity and employee candidate pool

- Faster sort speed will impact access to resources and increase production uptime

- Reduced training time

ALLIANCE SUPPORT

- Concept designed to fit your facility

- Install and training included

- Daily production report available

- Remote service access

- One year warranty

- Assigned service team

ADDITIONAL OPTIONS

- Peripheral equipment integration

- Tipper infeed

- Turntable outfeed

- Multi-robot dismantler layout

- Multi-year service plans

- Consumables replacement plan

Empower your growth with EQUIPMENT FINANCING!

Structured financing allows you to get maximum benefit from your investment with minimal bottom line impact, all while building equity towards equipment ownership. We have partnerships with long-tenured lease and finance managers who understand the industry to help you to explore all of your options. Learn more about our financing options.

You Can't Afford Not to Adopt Automation

Think automation is too expensive for your business? Think again.

With the help of our current automation users, we have developed a payback calculator to show how affordable adopting automation is. Click the link below and enter in your company’s data to see just how cost-effective automation can be for you.