Visit us at upcoming events

Our team is ready to help you find the best solution to solve the challenges your business is facing. We offer a variety of solutions for manufacturing operations. We look forward to seeing you at our next event!

MEET WITH OUR TEAM AT

BOOTH 2802

Discover the difference

Our team is ready to help you find the best solution to solve the challenges your business is facing. We offer a variety of solutions for manufacturing operations. Complete this form to connect with an automation expert.

SCHEDULE A MEETING

JOIN US AT

& NWPCA FALL PLANT TOURS

Montréal, Québec, Canada l October 3-5, 2023

Alliance Automation has partnered with IVISYS to provide accurate, reliable, and qualitative pallet inspection technology to streamline your sort and repair operations.

Meet our team, learn more about our partnership with IVISYS and see the Robotic Pallet Dismantler live at Interco on the plant tours.

If you have questions or want to connect with our team at Interpal, please fill out the form below.

OPEN HOUSE RECAP

a Glimpse into the Future of the Pallet Industry

Alliance Automation, a cutting-edge pallet industry solutions leader, opened its doors to customers and industry enthusiasts on November 16, 2023, for an exclusive Open House event. The spotlight of the day was on the highly anticipated Badger Sawmill Series, Pallet AI Inspection System, and Autonomous Forklifts. The event showcased the seamless integration of these technologies, offering a glimpse into the future of efficient and sustainable manufacturing and warehouse operations. Learn more about the open house and our featured products below:

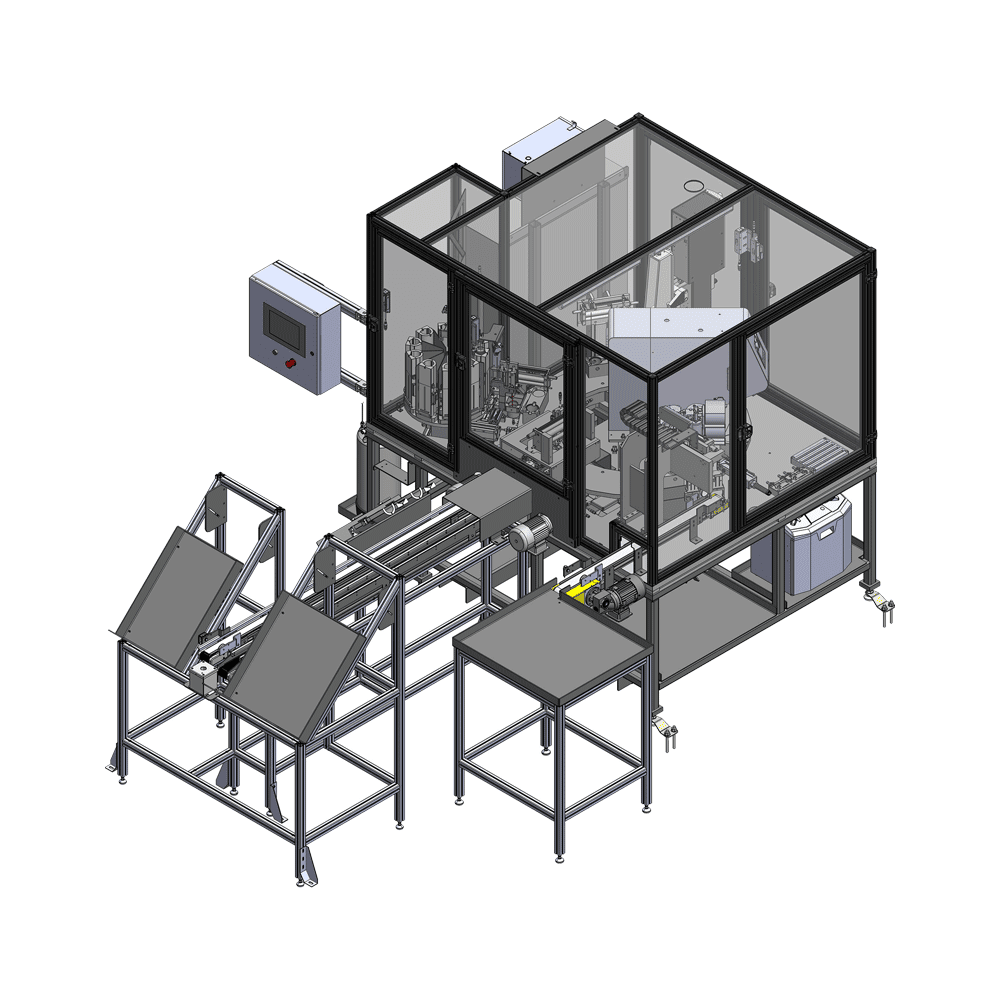

The Badger Sawmill Series, a marvel of engineering, took center stage at the event. This second-generation sawmill option was designed for pallet facilities with space limitations, but still required the functionality of scanning every piece of lumber using our vision system. With its compact footprint and state-of-the-art automation capabilities, the Badger will revolutionize the way companies handle and maximize processing reclaimed wood from dismantled pallets.

Equipped with precision sensors and automation, the Badger efficiently scans, optimizes, trims and sorts processed recycled lumber with unprecedented speed and accuracy, at an affordable price point for smaller pallet shops. The system’s intelligent algorithms ensure minimal waste while optimizing the use of each board. Attendees marveled at the machine’s ability to seamlessly adapt to various wood sizes and types, with a minimal footprint and human resources.

As the pallet industry continues to evolve, it is morphing into a fight for better information and flawless pallets. Pallet companies receive truckloads of pallets that they manually sort to evaluate pallets that need repaired, torn down, or can be resold. The biggest impacts to the industry are customer’s retaining the good pallets and shipping out the bad, pallet facilities needing to sort and fix the pallets as quickly as possible to get them out of the facility with limited human interaction, and finally ensuring each pallet meets the customers expectations to fit into their automated storage and retrieval systems (ASR’s).

Industry 4.0 will provide each pallet facility with live data feeds of production information as it is collected, not just at the end of the day. Software will be incorporated into automation equipment and the Pallet AI inspection system to allow for trending and production overviews in real-time or via a query based on dates and times. The software will have predictive maintenance capabilities based on reoccurring downtime tracking, which will alert management and Alliance Automation’s service team.

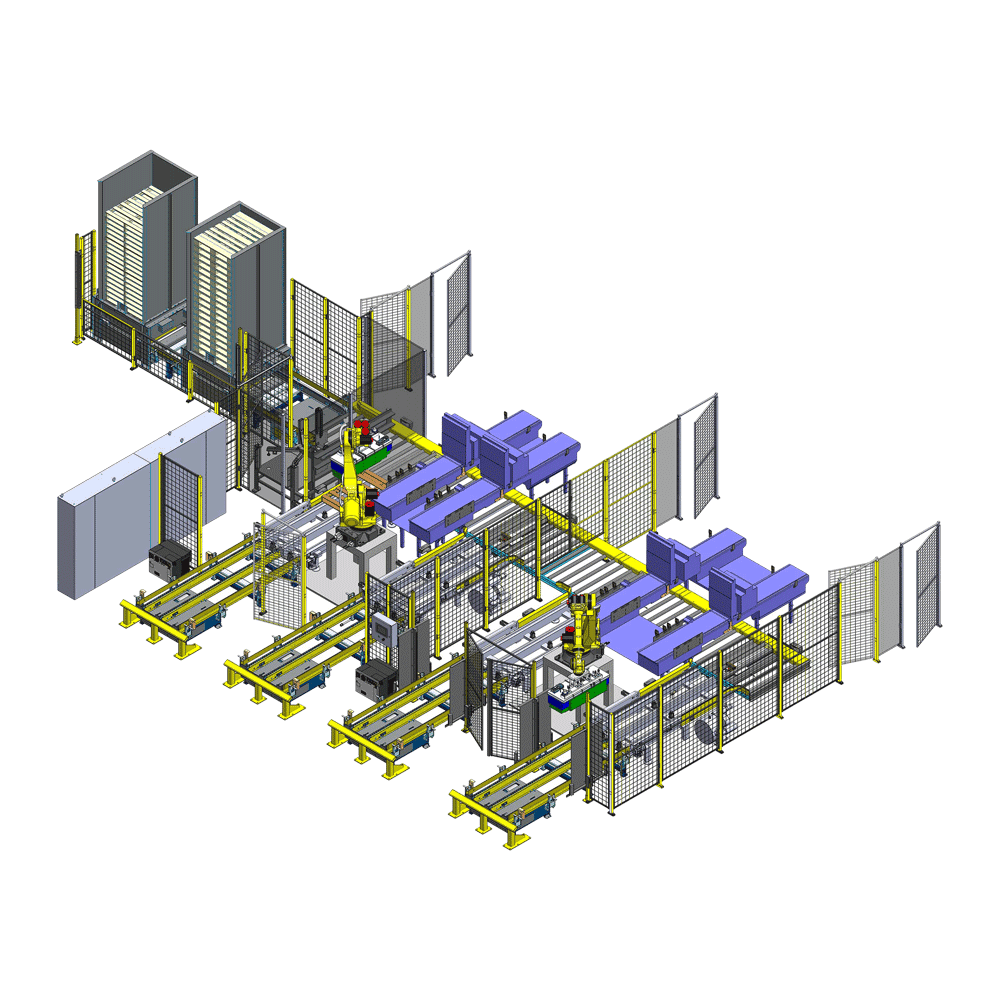

Alliance Automation also introduced its fleet of Autonomous Forklifts, showcasing their potential to transform logistics and material handling. These AGVs, equipped with advanced navigation systems, effortlessly moved through the facility, loading, unloading, and transporting wood pallets with precision and safety.

The AGVs demonstrated their ability to navigate dynamic environments, avoiding obstacles and adapting to changes in real-time. This flexibility positions them as a key player in the evolving landscape of smart manufacturing. Attendees were particularly impressed by the AGVs’ efficiency in optimizing material flow and reducing operational downtime.

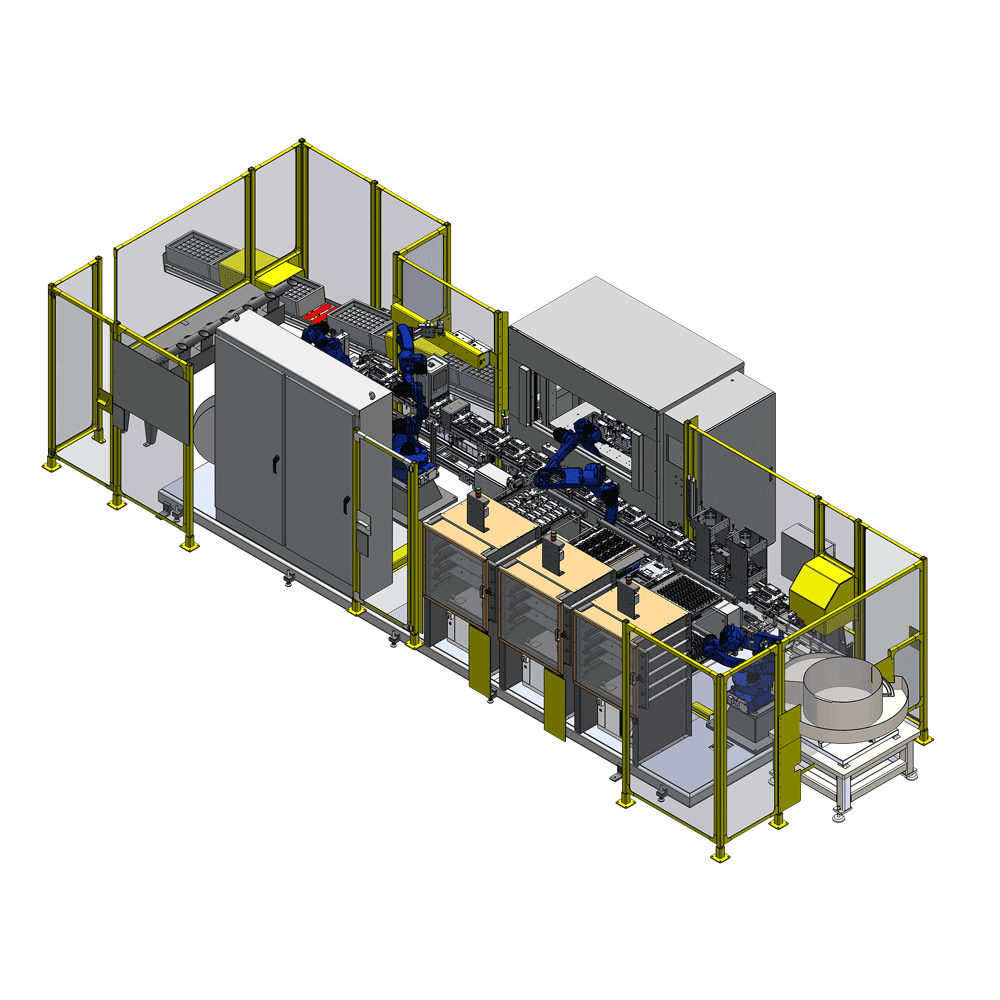

The speed and accuracy of inspecting each pallet coming into a pallet facility, knowing what to do with each pallet, and repairing only specific items on a pallet is becoming a must have for every facility. The open house showcased different layouts for sort & repair systems, but the Niagara Pallet system received a lot of attention with the capability of processing 1,000 pallets per hour and the integration of the Pallet AI inspection technology.

This next level sort & repair system incorporated the use of the AGV’s to load pallets onto the sortation line and then feed onto a pallet tipper that cingulated each pallet through the Pallet AI inspection system. From the inspection point a pallet was sorted into three categories; tear down, repair, sent to stacker to leave the facility. Tear down pallets went to a Robotic Pallet Dismantler, repair pallets went to a repair station that will show what items need to be replaced on a screen to streamline repairs.

The Open House wasn’t just about the impressive technology on display; it also provided a platform for industry professionals to share insights and discuss the future of automation. A panel discussion with leadership from Alliance Automation, IVISYS, Niagara Pallet, and Exeogen about the need for Industry 4.0 in the industry took center stage during the open house. Presentations from Alliance Automation experts during the tours allowed the industry to learn more about the impact of technology into everyday pallet processes. The flow of the open house allowed attendees to connect with like-minded individuals, fostering collaborations and sparking discussions about the transformative impact of these technologies on their respective industries.

This glimpse into tomorrow’s pallet industry left attendees with a sense of excitement and anticipation for the future. The automation solutions showcased not only the technological prowess of Alliance Automation but also the company’s commitment to sustainability, efficiency, and innovation.

VISIT US AT AUTOMATE 2023

BOOTH 200

Automate offers an opportunity to see state-of-the-art automated equipment and make new connections. Our team looks forward to forming new relationships and continuing existing relationships. Visit us at Automate in booth 200.

Integrators of Manufacturing Automation

Automotive Projects

Delivering automated assembly to save time, increase capacity, and improve safety.

Manufacturing

Projects

Providing higher productivity, reliability, and quality to fit manufacturing needs.

Material Handling

Projects

Supplying superior solutions for high-quality industry standards.

ALLIANCE

AUTOMATION

JOIN THE ALLIANCE

Have questions and want to get in touch directly with our team? Email us or give us a call today!