-

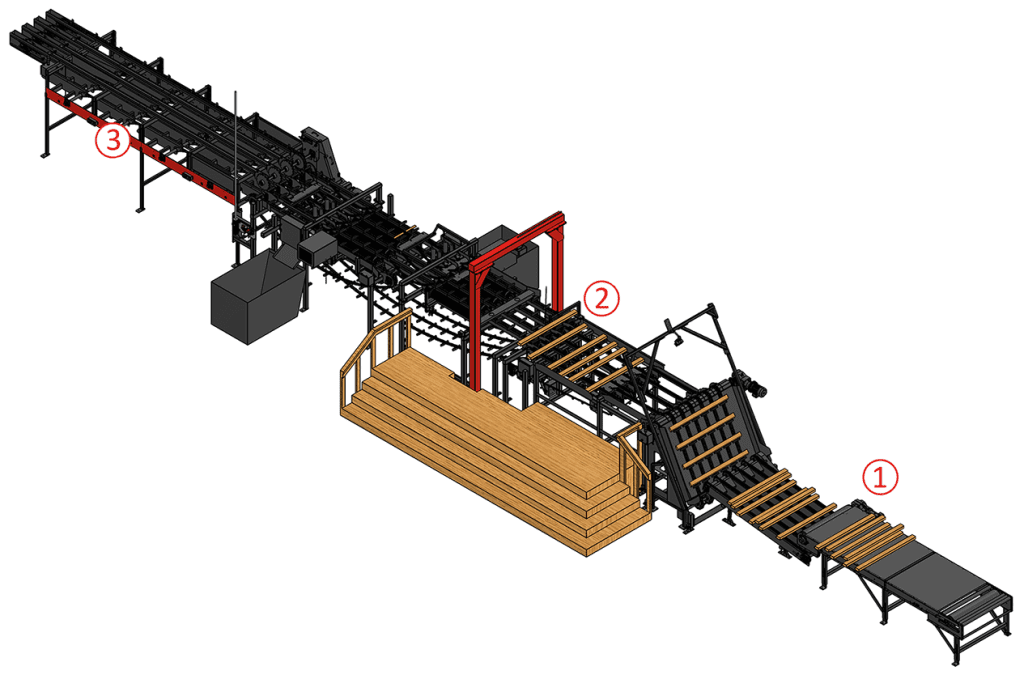

COMPONENTS

-

1. Infeed Section

-

1a. Optional: Lumber Dumper

-

Feed Conveyor

-

Drop Deck

-

Unscrambler

-

2. Optimization Section

-

Staging & Lug Chain Deck

-

Paddle Fence Module

-

Trimming Module

-

Vision & Laser Scanning

-

MCC/PLC Cabinet

-

Software Application

-

Operator Platform

-

3. Outfeed Section

-

Conveyor

-

Drop Sorter

-

Bulk Bin Sort Categories

Customization based on your needs.

Increase the feed speed withThe Robotic Pallet Dismantler

Combine with our Sort & Repair Systems

The Urban Sawmill

Up to 32,400 boards per shift

The increased reclaimed wood from the Robotic Pallet Dismantler gave rise to the next automation challenge; sorting and cutting. The Urban Sawmill processes individual pieces of lumber through a vision system to determine length, width and thickness to trim the lumber to the preset dimensions to maximize every piece of lumber. The cut lumber is then dropped into the appropriate bin to remove the need to manually stack the lumber.

From the first board to the last board cut, you will have accurate inventory to sustain your business.

THE URBAN SAWMILL PRODUCT BROCHURE

Take a closer look at the benefits your company will gain with The Urban Sawmill. Follow the link to download the brochure.

The Urban Sawmill FAQ

DELIVERY AND PRICING

- The average lead time is 16-18 weeks.

- This depends greatly on all the available options and how it fits into your layout and building.

- For the “standard Urban Sawmill”, it would be roughly $850,000.

- The Core System is the Unscrambler, Staging and Lug Chain Deck, Operator Deck, LH Operator Position, Paddle Fence Module, Flat Bar Trimming and Chains Module with 4” Cut Length on both sides, Single Camera Optimization System, Controls System, Standard Operator Platform

- In-Feed Conveyor System consists of Drop Deck Chain Conveyor and Flat Belt Conveyor (10’ to 50’ in 5’ Increments is Standard)

- Outfeed Conveyor System consist of Bulk Bin Sort Deck (4 to 10 categories in sets of 2 are standard) and Basic Machine Guarding.

- Shipping costs are not included in the quote for the Urban Sawmill.

- Customers may arrange shipping at their own expense. Standard System Requirements are (3) 53’ Conestoga (Curtain Side) Trailers, (1) 53’ Standard Dry Trailer. Alliance Automation can arrange shipping. A quotation will be provided upon request.

- The shipping cost in this quotation is only an estimate. At the time of shipment, costs will be reevaluated, and any additional costs will be passed to the customer.

- Alliance is responsible for rigging equipment onto trucks at Alliance Automation in Van Wert, Ohio. Customers will be responsible for rigging equipment and placing the equipment on the floor where it is to be installed.

- The customer is responsible for providing all required rigging equipment needed during installation including a 10-ton forklift with 8’ extensions or equivalent equipment required for the Urban Sawmill. In the event the customer cannot provide this equipment Alliance Automation will provide the equipment at an additional cost to the customer.

- The payment terms for the Urban Sawmill is 50% Invoiced upon Receipt of Purchase Order, 40% Invoiced prior to shipment of Equipment, and 10% Invoiced upon completion of installation. Due Net 30 Days, payments must be in U.S. Dollars

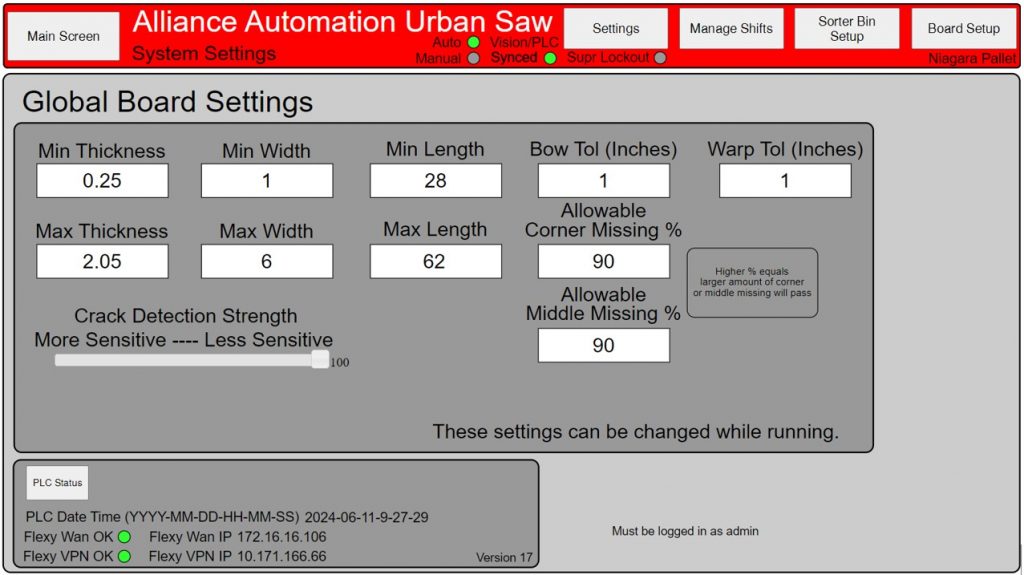

SCANNING AND BOARD TYPES

- Width: 1.5” to 8.0” @ 85%

- Length: 28” to 62” @ 85%

- Thickness: 3/8” to 2” @ 85%

- Warped and bowed boards will affect cut and measurement accuracy.

- Width (Height): 1.0” to 4.0” @ 85%

- Length: 28” to 62” @ 85%

- Thickness: 1” to 2” @ 85%

- Requires more frequent blade change

- Warped and bowed stringers will affect cut and measurement accuracy.

- Normal operating speed: 75 lugs per minute

- Maximum operating speed: 90 lugs per minute

- The Urban Sawmill will check for Length x Width x Thickness

- As for defects:

- It can help determine the percentage of the end of the board that is missing and determine the best utilization – We call this “percent corner missing,” and it is a global variable you can adjust

- A global “percent middle missing” variable can also be adjusted.

- The system does not grade.

- If both ends are within the allowable “percent corner missing” specification, and the first saw can remove the Length of material required, the system takes the full cut at saw #1

- Suppose one or both ends fall outside the “percent corner missing” parameter. In that case, the system determines how much material needs to be removed to make the end fit the parameter and will cut one or both ends accordingly.

- If the system needs to cut a length off a board that exceeds the first saw’s capacity, saw #1 cuts as much as it can, and saw #2 removes the remainder.

- When you set up a bin, there are selections for “board,” “2-way stringer”, and “4-way stringer. The system treats boards and 2-way stringers the same. If the setup is configured to 4-way stringers:

- The lug loader must ensure the notches are facing forward on the chain.

- If the lumber cannot be cut into any bin setups you have active, the board simply passes through the entire system and is rejected out of the end of the machine.

- If the incoming board is outside of the base parameters of the machine (Less than 28″ long, over 62″ long, or too narrow), the vision system will stop the machine, and that board must be removed from the saw deck chain.

The percentage that you set for corner and middle missing is the allowable percentage of the width, or middle of a board you don’t mind missing on good boards. Default setting of 90 means 90 percent of the corner or middle can be missing on a good board (3.5” wide board could have 3.15” missing and still be good). If the board is being cut down to fit a board spec., the final cut board is where the percent missing will be checked (a missing corner could be cut down to remove the part that had too much missing). The vision system needs about an inch of board on the ends of width, to measure the length accurately but makes the missing determination on the final ends of the board.

Crack sensitivity allows for adjusting how large of a crack in the board the system should allow. Most customers set the sensitivity to 100% and let the pallet assembly person determine if the board is acceptable, but setting for more sensitive (near 0) will reject boards with visible cracks.

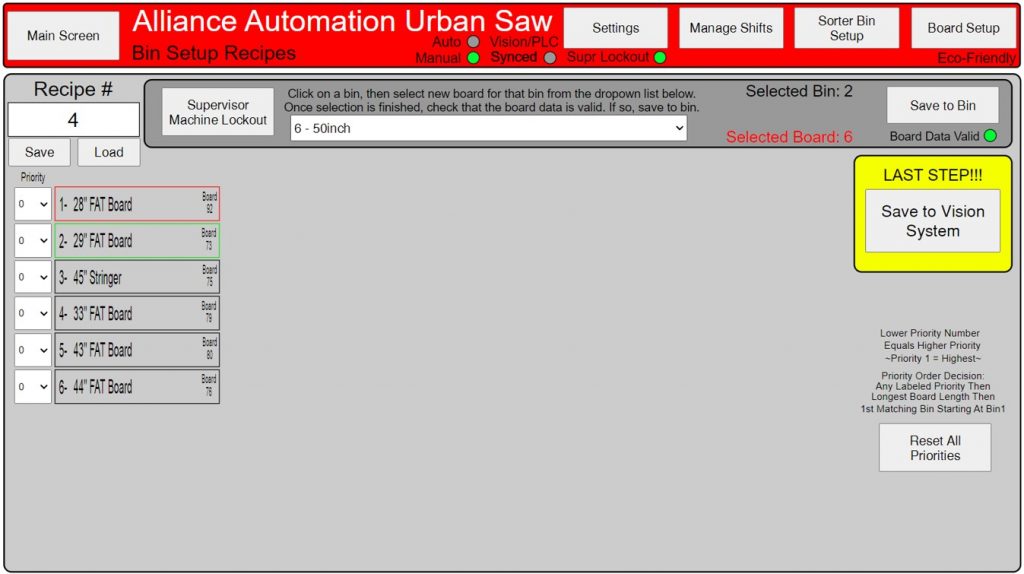

- The recipes were added to the USL to allow for storage and retrieval of board types and their associated bins and priorities. When the USL is setup for a certain customer or variety of lumber that will be sorted, this configuration can be saved in one of 10 different memory locations. When this configuration needs to be run again, it can be loaded from the memory thus saving some time setting up the machine for frequently used setups. The recipe stores the boards configured for each bin and the associated priorities. It does not save board specifications. Any time a board specification is changed, the new values will be loaded with the recipes.

With Supervisor Machine Lockout enabled, select a recipe number between 1 and 10 and press save to copy boards and current priorities into that memory location. Later, after running a different setup, the previous saved configurations can be loaded by entering the number that they were saved as and pressing load. It may be a good idea to create a record of what is saved in each location to prevent overwriting recipes.

BLADES

- This is difficult to calculate because it is based on each customer’s re-sharpening cost However, the blade is a carbide-tipped blade that can and should be re-sharpened.

- If you are only running deck boards, figure on replacing the blades every 30,000 boards

- If you are running only stringers, every 15,000

- If you are running a mix, somewhere in between.

- If you maintain the above schedule, the blades should only need re-sharpened and maybe one carbide replaced.

- Check the blades every 2-4 hours. When 1 or 2 teeth are missing, replace them with a re-sharp. If you continue to run the blades until you are missing several teeth, the re-sharpening / re-tipping costs become prohibitive. Therefore, keeping it to re-sharp and 1-2 tooth re-tip seems most cost-effective.

BINS AND SORTING

- This depends on the number of sort categories you require, and it is different for everyone.

- Some companies might have 6-8 dedicated to deck boards for repair, 2-4 for tighter tolerance lumber to go to a Viking, and a couple for stringers.

- I would say 10-16 is most common, there are a couple 20’s, but that is not as common.

- Companies like to make the rack out of pallets, and others get the nice stackable bins.

- If you are referring to the small cubby holes, we have only sold a couple to small shops.

- An operator’s time managing the small bins does not justify them.

- Most all systems go with bulk bins.

- There is a pull cord there that they are supposed to use if they lean in

- If they do not use it, then the system will run, not knowing they are in there

- There are many things you could do to prevent this, but all come at a cost people are not willing to pay for.

- The blade life can vary greatly with blades from different manufacturers and condition, but the average expected blade life is 40,000 to 50,000 cuts for a new blade. Sharpened blades seem to last a bit less than new with about 30,000 to 40,000 cuts. The number of cuts is kept in the saw control pop-ups, which need to be reset manually when a blade is changed out.

INSTALLATION AND THE FACILITY

- Customer will be responsible for the pneumatic connection from the facility air supply (plant air) to the Alliance cell drip leg connections.

- All other internal cell pneumatic connections are the responsibility of Alliance during the main panel disconnect lugs.

- All other internal cell connections and terminations will be made by Alliance during

- Customer will be responsible for the electrical connection from the facility buss bar to

- The customer is responsible for all electrical, communication, air and plumbing service drops required for the proposed equipment.

- Customers facility must supply electrical and pneumatic drops to the Urban Sawmill. The Urban Sawmill requires 220 volts / 3 Ph / 60 Hz / 500 amp fused service or 400 amp breaker service

- Clean dry air at 70 CFM @ 80 psi

Temperature of 32℉ to 104℉ or 0℃ to +40℃

Concrete floor with a minimum thickness of 8”. This system will need to be anchored in concrete at installation.

Notify Alliance Automation of any in-floor heating in the area of where the equipment is being proposed.

A customer supplied Ethernet connection is necessary. If an ethernet drop is not provided during the time of installation, travel costs will be charged for adjustments to equipment if a technician needs to travel on-site that could have been done remotely. This charge will be applied even during the warranty period. If an ethernet drop is not provided during the time of installation, daily reports will not be sent.

- Boards with long nails sticking out. More often than not, they will “fail to fence” and get rejected. They do not stop the system but do not get cut.

- The learning curve with board setup. If you try to set your bins up with too tight of a tolerance or have gaps in setup parameters from one bin to the next, you will get a high reject count because the lumber could not be processed into the bins set up.

- Maintenance: minimal maintenance is required with the system, but the little that is needed must be performed. The manual has a complete maintenance schedule, and maintenance training is part of every system.

BENEFITS

- Increase throughput of cut lumber

- Process boards and stringers at the same time

- Ensure lumber is cut to maximize every piece

- Eliminate the need for multiple manual saws

- Ensure a safer work environment

ALLIANCE SUPPORT

- Concept designed to fit your facility

- Install and training included

- Post install support

- Daily production report available

- Remote service access

- One year warranty

- Assigned service team

ADDITIONAL OPTIONS

- Multiple infeed options

- Bulk vs. hand unload

- Custom configuration of sort categories

- Peripheral equipment integration

- Sawdust/scrap conveyance

- Multi-year service plan

Empower your growth with EQUIPMENT FINANCING!

Structured financing allows you to get maximum benefit from your investment with minimal bottom line impact, all while building equity towards equipment ownership. We have partnerships with long-tenured lease and finance managers who understand the industry to help you to explore all of your options. Learn more about our financing options.

You Can't Afford Not to Adopt Automation

Think automation is too expensive for your business? Think again.

With the help of our current automation users, we have developed a payback calculator to show how affordable adopting automation is. Click the link below and enter in your company’s data to see just how cost-effective automation can be for you.

CASE STUDY

Maximizing Yield and Efficiency

How Georgetown Pallet Transformed Operations With The Urban Sawmill

Georgetown Pallet, a leading player in the pallet manufacturing industry, was facing significant challenges in utilizing and maximizing the yield from their manufacturing processes for new, recycled, and remanufactured pallets. As a response to these challenges, the company turned to an innovative solution – the Urban Sawmill. This case study explores the journey of Georgetown Pallet in integrating the Urban Sawmill into their operations, highlighting the value and efficiency it brought to their manufacturing processes.