Choosing the Right EOAT for Robotic Pallet Dismantling

Written by Anthony Buzard, Automation Sales Engineer, with assistance

How We’ve Continued to Improve the Robotic Pallet Dismantler EOAT

At Alliance Automation, we don’t believe automation is ever “done.”

If there’s a safer, more reliable, or more efficient way to do the job, we’re going to chase it, even if that means rethinking components that already work.

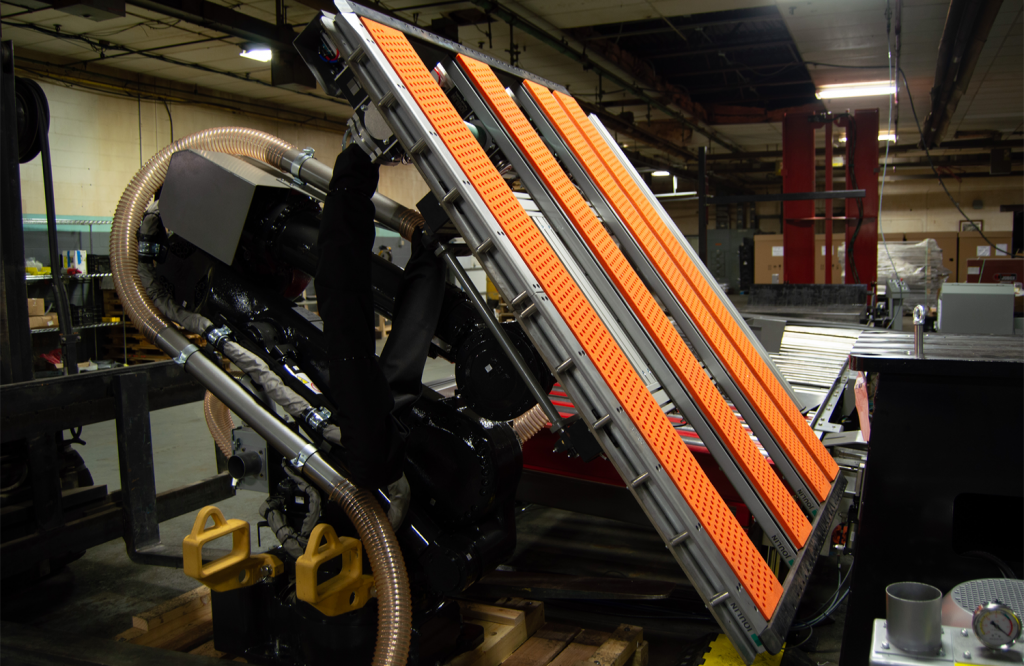

A great example of that mindset is the evolution of the end-of-arm tool (EOAT) on our Robotic Pallet Dismantler.

Over the years, we’ve deployed three primary EOAT approaches:

- Our original foam-based EOAT

- An improved foam design

- And now, a mechanical gripper end-of-arm tool

Each option serves a purpose, and each was developed based on real-world feedback from pallet recyclers running production every day. Below is a practical breakdown to help you understand the differences and decide what makes the most sense for your operation.

The Tried-and-True Option: Original Foam EOAT

The foam-based EOAT is where it all started.

This design helped establish robotic pallet dismantling as a safe, scalable alternative to manual teardown, and it is still running successfully at dozens of facilities today.

Key capabilities:

- Up to 100 pallets per hour

- Handles 30×30 up to 60×60 pallets

- Complete dismantle of stringer and block pallets

- Proven across 80+ systems in the field

Tradeoffs to consider:

- Larger system footprint

- Higher cost of entry

- Foam replacement

Foam life (original design):

- Approximately 3,000 pallets per foam pad (site dependent)

- $224 per foam piece

- 4 foam pads per EOAT

(Fingers 1 & 2 typically wear faster than 3 & 4)

This version remains a solid, dependable solution, especially for operations that need maximum pallet size flexibility and full dismantling capability.

Refining What Works: New & Improved Foam EOAT

As more systems went into the field, one thing became clear:

Foam life mattered more than we originally thought.

So, we went back to the drawing board.

Without changing the core concept, we refined materials and geometry to dramatically improve durability, and the results have been significant.

What’s improved:

- Customers are reporting up to 15,000 pallets per foam pad

- Same $224 per foam piece

- Same 4-piece EOAT configuration

- Same throughput and pallet size capability as the original foam system

That’s five times increase in foam life in many applications, directly reducing consumable costs and maintenance interruptions.

This is a great example of how we approach system refinement:

- Listen to customers

- Analyze wear data

- Improve the design without overcomplicating it

The New Option: Mechanical Gripper End-of-Arm Tool

For some customers, the next logical question was simple:

“Can we eliminate foam entirely?”

That question led to the development of our Mechanical Gripper End-of-Arm Tool.

Mechanical Gripper EOAT capabilities:

- Up to 90 pallets per hour

- Handles 30×30 up to 50×50 pallets

- Complete dismantle of stringer pallets

- Block pallets are cut down into dumbbells

- Mechanical gripping with no foam consumables

- Compact system footprint with fewer wear components

This solution trades some throughput and pallet size range for simplicity and durability, and for the right application, it is a clear win.

So… Which Option Is Right?

There’s no one size fits all answer, and that’s intentional.

At Alliance Automation, we don’t push a single configuration. We help customers choose the option that fits:

- Their pallet mix

- Their throughput goals

- Their maintenance preferences

- Their available floor space

Whether that’s:

- A foam-based system with maximum flexibility

- An improved foam solution with extended consumable life

- Or a mechanical gripper EOAT built for simplicity and durability

Always Improving Because Your Floor Isn’t Static

The Robotic Pallet Dismantler has been in the field for years, but it hasn’t stood still.

Every iteration, from old foam to new foam to the gripper, reflects the same philosophy:

- Build what works

- Learn from real production

- Improve relentlessly

That’s how we approach every system we design, not just pallet automation.

Innovate. Create. Advance.

We build the machines that let you build your products.

If you’re evaluating pallet dismantling automation or wondering which EOAT makes sense for your operation, let’s talk. Contact us at 419.238.2520.