OPEN HOUSE

Wednesday, July 16, 2025

Alliance Automation l 1100 John Brown Rd l Van Wert, Ohio 45891

A CLOSER LOOK

Open House Agenda:

MORNING SESSION 9:00am-12:00pm:

Arrival & Registration: 9:00am – 9:30am

-Coffee, donuts & greetings-

Alliance Presentation: 9:30am – 10:00am

-Doug Wenninger – President/CEO of Alliance Automation-

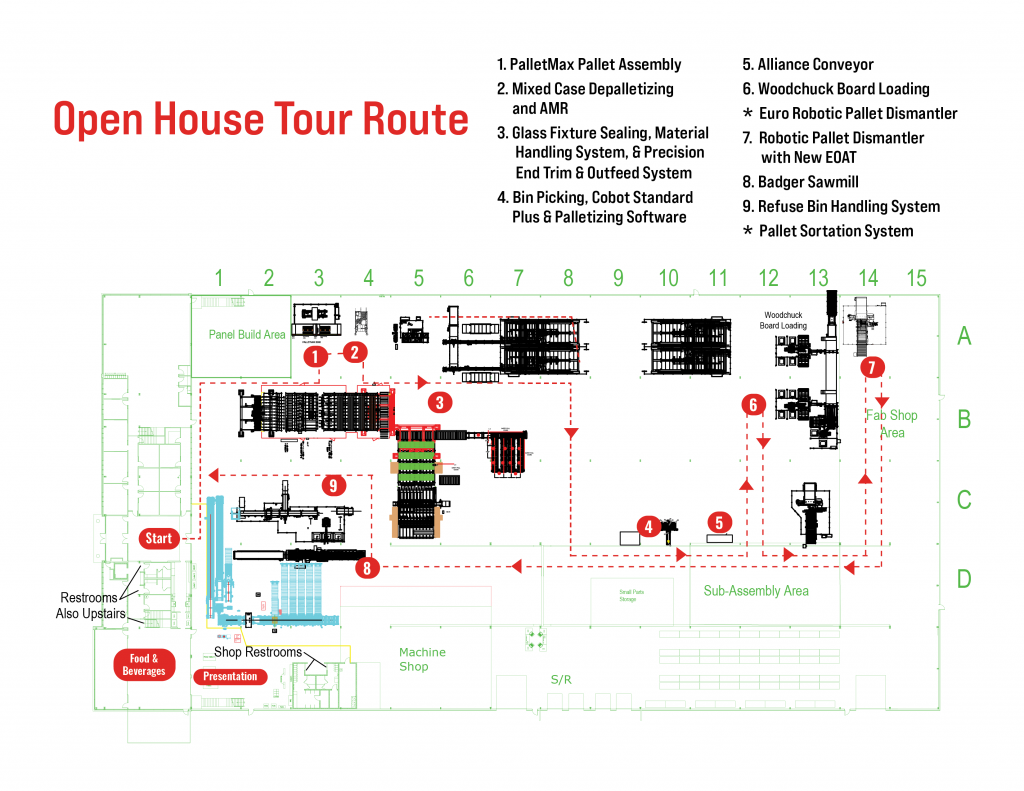

Plant Tour: 10:00am to 11:30am

Q&A Session: 11:30am to 12:00pm

AFTERNOON SESSION 1:00pm-4:00pm:

Arrival & Registration: 1:00pm – 1:30pm

-Refreshments, snacks, & greetings-

Alliance Presentation: 1:30pm – 2:00pm

-Doug Wenninger – President/CEO of Alliance Automation-

Plant Tour: 2:00pm to 3:30pm

Q&A Session: 3:30pm to 4:00pm

Station 1: PalletMax

7 sold in the US in the last 8 weeks, 125 installed in Europe

Pallet production equipment is designed to produce non-standard and standard pallets. Making the work easier for employees, there is no need to hammer pallets, the installation does this work for them. Easily and quickly changeable pallet templates allow you to quickly adjust the equipment to produce different pallets.

Station 2: Mixed Case Depalletizing

QuickBot depalletizer reduces onsite deployment time by providing you a drop-in-place solution that requires no connection to upstream systems, zero engineering and no programming off-site.

- Configured to meet your unique needs

- Manage variable pallet loads

- Automation to optimize product handling

- Proven technology in production environments

- Software capable of autonomous decision making

Station 2: AMR

Delivering end-to-end AMR and AGV solutions tailored to your operations, Alliance represents 3 companies (VisionNav, Kuka, and Seer). From system design and seamless integration to fast deployment and hands-on training, we ensure minimal disruption and maximum efficiency. With smart automation, real-time insights, and ongoing support, we help you reduce downtime and stay ahead.

- Increased Operational Efficiency

- Reduced Labor Costs

- Improved Safety

- Better Inventory

- Material Handling

- Data Collection & Analytics

- Consistency and Accuracy

- Flexibility and Scalability

- Improved Security and Traceability

Station 3: Building Materials

Material Handling System

This turnkey automated Material Handling system for extruded board processing handles multiple operations including automated stacking of extruded boards, manual stacking of extruded boards, automated transfer of extruded boards from the cut location to the oven conveyor loading gantry, automatic loading of trays for oven transport, and communication to the oven.

Once the boards are completed in the oven, the system will communicate with the oven, and then convey the boards to the Precision End Trim and Outfeed system.

Functions the cell will perform:

- Extrusion Handling: Automated sweeping, gantry loading, RFID carts/docks

- KUKA AMRs: 10 mobile robots

- Oven Transfer: Gantry/cart to oven, conveyor in/out, unload to trim line, RFID data to oven

Precision End Trim & Outfeed System

The automated Precision End Trim and Outfeed System for extruded board processing handles multiple operations including receiving boards from an infeed conveyor, accurate placement of boards prior to trim, trim, automatic rejection, manual end tagging, outfeed stacking, manual wrapping and automatic banding, and automatic transfer to an outbound location for fork truck pickup.

Functions the cell will perform:

Trim:

- Singulation, end justification, precision trim

- Board rejection and flipping by product matrix

- Layer accumulation (2 operator stations)

- Layer stacking and transfer to banding conveyor

- Manual protection board loading based on product matrix

Wrapping & Banding:

- Manual bagging zone

- Automated banding, board and edge protection

- Transfer to Lift & Transfer conveyor for offload

Bunk Offload:

- Lift & Transfer to offload area

- Multi-bunk transfer for forklift loading

Station 3: Glass Fixture Sealing

This system involves preparing each station and adjusting the fixture plate to fit various glass pieces, ensuring proper positioning for the next steps. An operator tilts the frame to load the fixture plate onto the sub-weldment plate, which is then lowered flat for the robotic seal application. The robotic system applies the seal uniformly to each glass piece. Once the seal is applied, the operator unloads the glass pieces. All stations can accept all fixture plates for all glass models for operation.

Functions the cell will perform:

- Setup: Adjust fixture plates for glass type (Front/Rear, Quarter, Roof)

- Load Fixture: Tilt frame, load fixture plate, return frame to flat

- Load Glass: Manually place and align glass with sensors

- Seal Application: Select process on HMI, robot applies seal, system signals completion

- Unload: Remove glass, tilt frame, unload fixture plate

Station 4: Cobot Standard Plus Palletizing

Portable Palletizing Solution – Collaborative design assures safety, quality and precision, without safety fences.

- Easily transferred with pallet jack to another line

- Minimum space required

- No guarding required

- Productivity: 600 Boxes per hour

- Product Handling: Cardboard boxes

- Max Product Weight: 44 lbs

- 1 or 2 palletizing position

- Slip sheet compatible

- Small to medium productivity capacity

- Plug and play solution

- Easily programmed

- Comes AMR ready

Station 5: Alliance Conveyors

Industries need conveyors that are durable, efficient, and easy to maintain—qualities not every manufacturer delivers. Our new design tackles common issues like bearing failures, wear, and debris buildup with serviceable parts, accessible grease points, no hex shafts, and a sealed chainbox. Built tough for demanding conditions.

- Heavier frame construction

- Bigger rollers

- Serviceable sprockets

- Separate bearings

- Faster speed

- Exterior chainbox

Station 6: Woodchuck Board Loading

Pallet Nailer Loading – New Product Released in 2025

- Smaller Team, Greater Profits – Common pallet nailers require at least 3 people to operate. Our patent-pending Woodchuck needs just 1 person

- Automated Inspection System – Every board is scanned to meet your standards. Board orientations are corrected, and out-of-spec boards are rejected driving consistent pallet quality

- Fits common hopper – style nailing machines giving you flexibility to adjust your workflow to best fit your needs

- 9 Second Cycle Time – Meets the need for a wide variety pallet and wood types. Delivering consistent board feeds, the right orientation and quality

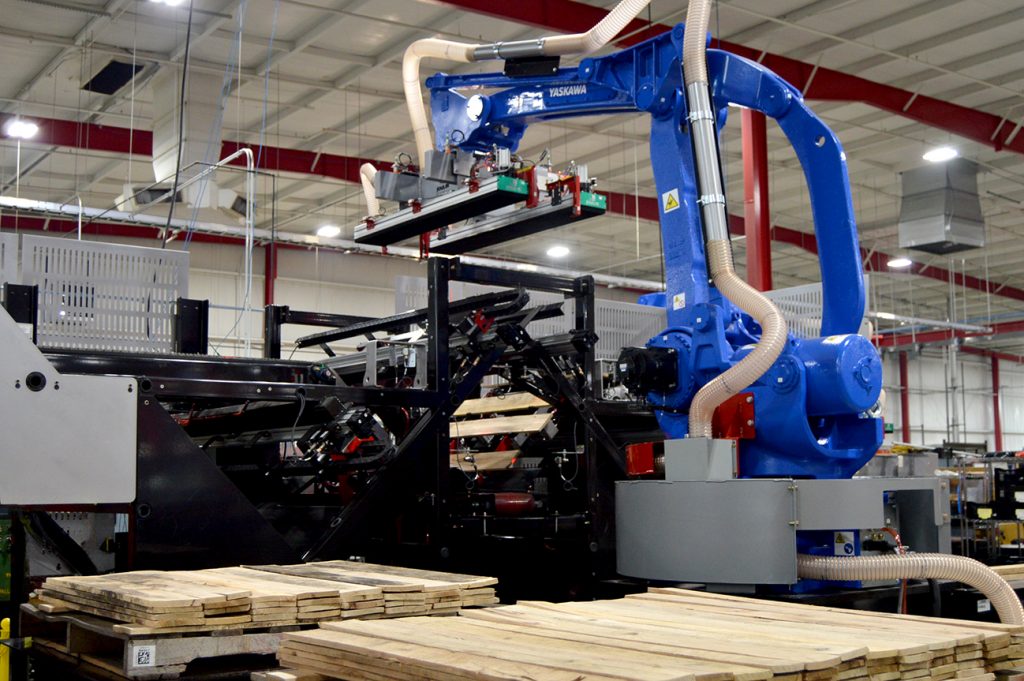

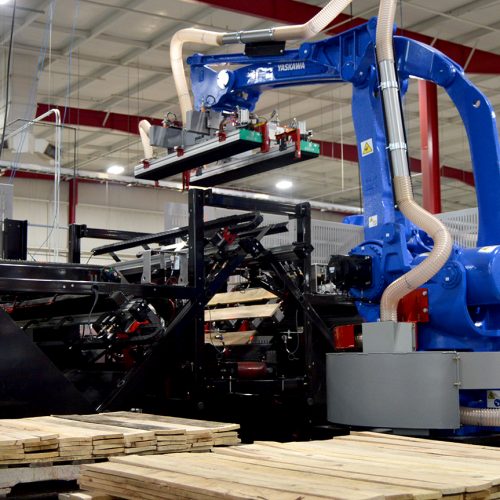

Station 7: Robotic Pallet Dismantler M-2

- Component Removal Ready

- No-Foam End of Arm Tool

- Robust Roller Infeed Conveyor

- Smaller Footprint

- Double Output

- Process More Teardown Pallets

- Consistent Throughput

- Eliminate Operator Fatigue

- Expand Available Labor

- Safer Work Environment

*We have expanded into the European Market: With growing demand for safer, more efficient pallet teardown solutions, Alliance Automation is proud to introduce our Robotic Pallet Dismantler to the European market. Designed for performance and operator safety, this cutting-edge system brings next-level automation to pallet recycling across Europe.

Station 8: Badger Sawmill

Up to 20,000 Boards Per Shift – New Product Released in 2023

- Developed in response to industry feedback on the Urban Sawmill – needing less expensive, smaller footprint option to scan, optimize, trim and sort boards

- Scan every piece of lumber through our vision system to determine length, width and thickness to then trim the lumber to the preset dimensions

- Smaller footprint

- Lower price

Station 9: Refuse Bin Handling

Waste Disposal Industry

The refuse bin handling system is designed to manage three types of bins: hinged lid, large snap-on lid, and smaller snap-on lid. Bins are manually loaded onto an infeed conveyor where they undergo barcode scanning and weighing to identify and ensure correct processing. After identification, the bins move to a robotic dumping platform before being placed onto a tunnel wash conveyor. Each dumping station is equipped with a high-resolution 23K industrial 3D sensor that reliably determines volume and guides the robotic dumping process. Following dumping, an AI-powered vision system inspects each bin to detect any remaining material. Additionally, a pass-through conveyor is provided to handle hazardous, pathological, chemical waste, or bins that are not fully emptied.

Functions the cell will perform:

- Infeed: Operator loads bins; system separates and conveys them

- Scan & Weigh: Vision system (5 cams), inline scale, bin centering

- ID & Rejects: Height sensors; undetermined bins sent to manual reject line

- Dumping: Centering holds bin; Fanuc robot handles bin/lid pick, dump, and wash tunnel load

- EOAT: Twin jaw gripper + vacuum lid tool; wash-down capable

- Autoclave Stations: 3 stations with 3D volume scan, sensors, lights, and manual access

- Bin Check: AI vision confirms bins are fully emptied

- Outfeed: Empty bins sent to wash system

Featuring palletizing, autonomous vehicles, pallet recycling and so much more.

-

Woodchuck

Automate board loading for pallet nailers, reducing labor to one operator while boosting speed, quality, and efficiency.Learn More -

Pallet Assembly

Builds standard and non-standard pallets with no manual hammering required. Quick-change templates make it easy to switch between pallet types.Learn More -

AMR/AGV

Navigates and transports materials independently, improving workflow efficiency, reducing labor costs, and increasing workplace safety. -

Robotic Pallet Dismantler

Increase safety, efficiency, and consistency by automating pallet teardown process - featuring NEW component removal.Learn More -

Palletizing

User-friendly, cost-effective solution with advanced reliability, small footprint, quick start-up, and low maintenance requirements.Learn More

SIGN UP TO ATTEND OUR OPEN HOUSE!

We are opening the doors to success.

Join us for a glimpse into the future of automation in our state-of-the-art facility.

FEATURED EQUIPMENT

PALLET & LUMBER:

Woodchuck Board Loader

Pallet Assembly

New End of Arm Tool (EOAT) for the Robotic Pallet Dismantler & M-2

US & Euro Pallet Component Removal

AI Vision

Alliance Heavy Duty Conveyors

CUSTOM AUTOMATION & MATERIAL HANDLING:

Palletizing Equipment

Mixed Case Depalletizing

Gantry Loading & Transferring

Autonomous Vehicles

Layer Accumulation & Stacking

Bin Picking

HOTEL ACCOMODATIONS

Below are options for hotel accommodations in Van Wert, Ohio, Lima, Ohio and Fort Wayne, Indiana.

*Please note there is no transportation in Van Wert, Ohio (Uber, Lift, etc.)*

Holiday Inn Express & Suites

Van Wert, Ohio

Book Your Room

419-238-2600

Fairfield Inn

Lima, Ohio

Book Your Room

419-232-6040

Courtyard by Marriott Fort Wayne Downtown

Fort Wayne, Indiana

Book Your Room

260-490-3629

Holiday Inn Express Fort Wayne-East

New Haven, Indiana

Book Your Room

260-748-6767

Learn more about our automation solutions

ALLIANCE

AUTOMATION

JOIN THE ALLIANCE

Have questions and want to get in touch directly with our team? Email us or give us a call today!