CRATE & PALLET ASSEMBLY

Pallet and crate assembly automation involves using advanced machinery and robotic systems to streamline the assembly process. This technology enhances efficiency by reducing manual labor, minimizing errors, and accelerating production rates. These systems are crucial in improving productivity, enhance workplace safety, and reduce operational costs. By integrating automation, companies can meet high demand with greater speed and accuracy.

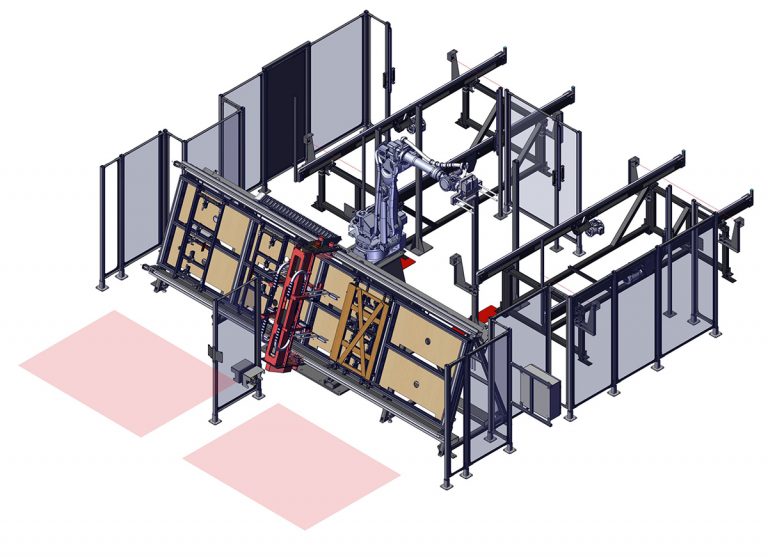

Crate & Pallet Component Assembly

UP TO 1,500 ASSEMBLIES PER SHIFT

Component Assembly

Making crates and pallets can be a cumbersome, slow, and difficult job. But it doesn’t have to be. The Alliance Automation Component Assembly Cell is adaptable to your needs, big or small. These production cells can build with multiple component types, yielding different crate or pallet sizes to fit your unique application. Changeovers are quick, production is safe, and operation is easy and ergonomic for maximum throughput.

BENEFITS

- Increase throughput

- Reduce fatigue, accidents and injury

- Easy/ergonomic loading

- Minimal changeover time

ALLIANCE SUPPORT

- Designed to fit your facility

- Installation and training included

- One year warranty

- Assigned service team

- Spare parts packages

STANDARD OPTIONS

- Pneumatic clamping or spring clamp fixtures

- Flexible or dedicated fixtures

- Multiple powered outfeed options

- Nested stacking (ability to flip product)

- Extended reach/payload robots available

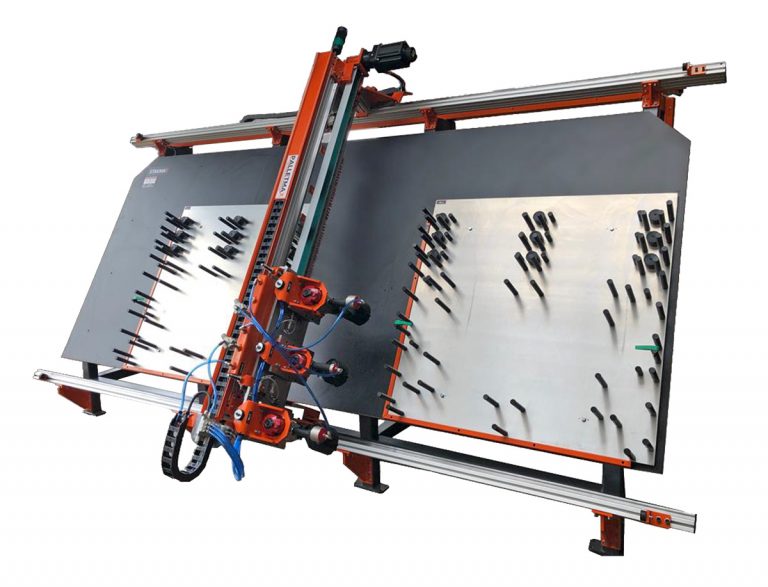

Pallet Building - PALLETMAX

Less workforce, more productivity!

Powered By STAKMA

Learn more about our partnership below

Operating the Machine

This is an easy and operator friendly system. Start-up, RESET, choose your program – that’s it. Let’s produce pallets!

Precision Positioning

PALLETMAX is equipped with precision and high durable servo motors. Motors are controlled by our system while operators can control the machine speed & acceleration.

Quick Dimensions Changeover

Pallet dimensions & pallet type can be changed in less than 5 minutes. No programming required after template change, operator chooses pallet dimensions from the list and loads program.

Low Requirements

PALLETMAX is a low-maintenance machine with minimal requirements. Its electricity and air consumption are significantly lower compared to other machines on the market.

Nailing Heads

No more manual nailing for the operators. As easy as possible operators collect boards into template on PALLETMAX machine and press START button for production. Nailing heads will do the rest of the work.

Partnered With

Partnering with STAKMA allows us to expand our range of solutions and better serve our customers. By leveraging each other’s strengths and expertise, we can develop innovative products and services that meet a wider variety of customer needs. This collaboration not only enhances our capabilities but also provides our customers with comprehensive, high-quality solutions, ultimately fostering stronger relationships and driving mutual growth and success.

Pallet Production

Pallet production equipment is designed to produce non-standard and standard pallets. Making the work easier for employees, there is no need to hammer pallets, the installation does this work for them. Easily and quickly changeable pallet templates allow you to quickly adjust the equipment to produce different pallets.

The device automatically counts the number of nails in the hammer guns. When the nails run out, the equipment automatically stops and informs the worker that the hammer gun is empty of nails.

PALLETMAX Options:

- Add up to 4 Nailing guns

- Working area up to 12000 mm

- Standard or Adjustable template

- Jumbo magazines up to 1200 pcs

- Extended online service

- Extended warranty

PALLETMAX Videos

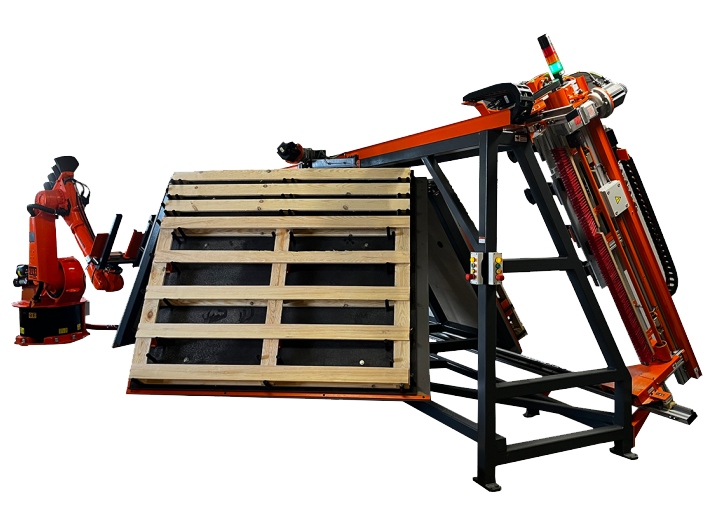

Pallet Building - PALLETSTAR

400-600 PALLETS ASSEMBLED PER SHIFT

Powered By STAKMA

Learn more about our partnership below

Operator Working Area

Operator loads boards & blocks to template for new pallet production and press Start button to rotate table to Pallet nailing area. After rotation completes, Operator continues to load boards & blocks to pallet template.

Pallet Production Area

After rotation completes, pallet nailing machine will produce pallet and in the same time Operator will load boards & blocks to template while Robot will pick-up produced pallet for automatic stacking.

Pallet Stacking Area

While Operator & nailing machine producing pallets, automatic pallet stacking robot pick-up pallet for stacking.

Nailing Heads

No more manual nailing for the operators. Operators collect boards into the template on the PALLETSTAR machine and press the start button for production. Nailing heads will do the rest of the work.

Partnered With

Partnering with STAKMA allows us to expand our range of solutions and better serve our customers. By leveraging each other’s strengths and expertise, we can develop innovative products and services that meet a wider variety of customer needs. This collaboration not only enhances our capabilities but also provides our customers with comprehensive, high-quality solutions, ultimately fostering stronger relationships and driving mutual growth and success.

Automatic Pallet Production

The PALLETSTAR is designed to produce standard and non-standard manufactured pallets up to 102 inches long. Tables are loaded into the pallet template manually. Easy to program and save pallets in Windows operating system.

Automatic unloading of pallets will facilitate the work of the operator, there is no need to unload pallets manually. After setting the number of pallets for stacking, the ABB Robot will automatically unload the pallets.

PALLETMAX Videos

Is Automotive Automation Right for your Business?

-

Is your current manufacturing process struggling to meet quality standards?

-

Do you have a new product or change to a product that you need to add to your production process?

-

Is it time for your company to bid for new business opportunities and gain assistance?

-

Have you struggled with labor requirements for production?

-

Are your current customers requesting new functions or testing to be integrated into production?

Why you should Join the Alliance

When you partner with Alliance Automation you're getting more than just a robotic solution.

Alliance Automation is here to design, build and install a custom solution to fit your exact needs. Our products will solve your business challenges. How? We follow the Alliance Proven Process. Alliance Automation doesn’t just sell you a product; we get to know your business and find solutions to help you reach your goals.

What we offer:

- Project Review

- Risk Analysis and Risk Assessments

- Budgetary and complete project proposals

- CAD Designers

- Fabrication

- Toolmakers

- Machinists

- Mechanical Engineers

- Electrical Engineers

- Controls Engineers

- Project Managers

- Full Implementation teams