Automation Integration – The Value of a Good Automation Partner

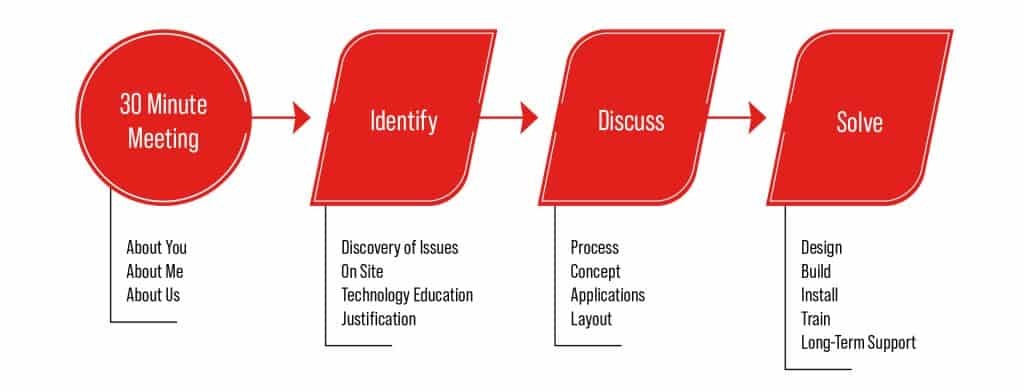

THE ALLIANCE PROVEN PROCESS

When an Automation Integrator Is Needed

Exploring the expanses of the automation world alone can feel like you’re a kid lost at the grocery store – kids will gravitate toward the candy or snack aisle long before they worry about finding their parents. Robots arms and fancy work cells are the candy in industry. While they are awesome, they need to be considered cautiously.

Many businesses are successful thanks to their smart and talented staff. Because of their success internally with other capital equipment, these facilities often try to add automation themselves, but it is easy to fall victim to the shiny “candy” that is a robot or a cumbersome solution. Taking on such a task internally is possible, but bandwidth can often become an issue very quickly.

It’s important to consider:

- Properly scoping the entire project

- Researching and purchasing all the proper equipment

- Installing equipment after delivery

- Testing and debugging the programming

- Adjusting robot logic

- Ensuring proper HMI is established

- Safety standards and requirements

Often facility managers will hire automation integrators, like Alliance Automation, to bridge the gap when these considerations are beyond the bandwidth or skill sets of their current staff. Like any other major business purchase, the success of adding automation is heavily dependent on Return on Investment (ROI) or more importantly, Internal Rate of Return (IRR). We’ll cover IRR in more depth in a future write-up.

The tipping point for many companies to add an automation integrator is when they can’t implement it cheaper themselves. This doesn’t take into account increased efficiencies, quality improvements, or positive impacts to labor further down the line or in the facility. Getting automation up and running quickly with an integration partner not only means less downtime in the facility, but it also means a better-running system (as well as more profitable) over time.

Thinking back to the kid in the grocery story analogy, you might be excited to spend the rest of your days in the candy aisle, but in reality, the value is short-lived. We all know the value of a balanced diet that is catered to your body’s needs, automation is the same. Your body needs veggies as much as your taste buds want a bag of Snickers – discovering your deficiencies helps to create a better plan of action for eating as well as automating.

An automation integrator is like a dietitian at the end of the aisle, pointing you toward the food (capital equipment and software) you actually need versus the candy that will make your temporarily happy (shiny robots that don’t match your challenges).Using an automation integrator may seem like a more expensive choice, but using IRR often proves that it saves money in the long run. Obviously, leveraging an automation integrator can help save time, but the time for reworking unexpected failures can be minimized with a partner.

Having qualified, outsourced eyes on your project can also help increase the buying power of the available capital. When equipment is properly scoped for the job at hand, it prevents over-buying. Less overhead in equipment and processes means employees can be more efficient and reduces the need for extra staff. Having an automation partner also means that staff won’t be preoccupied with developing the new system, and instead, can remain focused on their normal daily work.

Automation Integration at Work

Alliance Automation partnered with an organization that provides construction components, retail solutions, and packaging solutions worldwide. The organization has worked through a number of automation projects. The projects have ranged from assembly cells to simple vacuum stacking, and they plan to add more as they look for more efficiency.

After adding so much automation to their facilities, the organization has a fair amount of in-house automation expertise, but they look to Alliance Automation as leaders in the industry. Leveraging internal expertise alongside a partnership with an automation expert means they can concentrate on the granular elements of their business while the experts can use their broader experience to apply unique and valuable insight to their automation.

The company partnered with Alliance Automation because it was the first organization to provide valuable, industry-specific expertise. As the partnership has developed, the inner workings of the business have begun to work in concert with the Alliance Automation experts.

Some of the company’s biggest concerns about adding automation were management engagement and maintenance/personnel to support their endeavor. A leader in the company said, “Alliance didn’t alleviate the concern, BUT they did do an excellent job in support of our shortcomings.”

Finding a Good Automation Partner

From both an efficiency and profitability perspective, leveraging the knowledge and services of a quality automation integration partner is the best choice. But, choosing a partner can be a different challenge.

The best way to establish an automation partner is to have a discussion that focuses on your company, how the automation fits your needs, and how the two of you will work together to resolve the challenge. Their resources should expand beyond your industry and include the resources to support any equipment after installation.

A potential automation partner will spend time with you onsite at your location to identify challenges, provide you technical information that you may not be aware of, and to be honest about the need for automation. They should be discussing possible processes, concepts, applications, and layouts that could work for your facility.

While they will help solve the challenge presented, they also need to design, build, install, train, and provide your company long term support for your automation system.

Most automation is not an off-the-shelf option. Buying a robot doesn’t mean you’ve automated… that robot requires an array of systems to provide real value to a business. A good automation partner will share both their successes and failures, because nothing will ever go perfectly to plan. Understanding the equipment and systems well enough to adjust and adapt are signs of a qualified integrator.